Abstract:

In this experiment the tensile strength of cotton grey fabric was calculated having a plain weave design. The experiment was performed according to the ASTM test method D5035. The tensile strength of fabric from both warp-wise and weft-wise direction was calculated. It was noted that warp-wise strength of fabric is more than that of weft-wise tensile strength.

Introduction:

Tensile strength of the fabric means the strength along the warp-wise or weft-wise direction of the fabric. The textile fibers are anisotropic in nature, as the yarn is made of fibers and fabric is made of yarn, so the anisotropic behavior of fibers is clearly visible in the fabric. The tensile strength of fabric plays an important role in the quality of end product to be produced from it. Good tensile strength relates to the good life of fabric. So the tensile strength of fabric is checked after each chemical process and especially after the weaving process before any chemical treatment.

Tensile strength in a fabric depends upon many factors. The yarn properties plays key role in calculating the strength of the fabric. Many factors are as follows:

- Yarn spinning process i.e. Ring, Rotor, Vortex and Friction spinning.

- Composition of yarn i.e. spun or filament.

- Single or plied yarn.

- Count of yarn.

- Ends/inch and picks/inch in the fabric structure

- Weave type i.e. plain, twill or satin.

The tensile strength of fabric was tested according to ASTM Standard – D5035. The tensile testing machine works on the CRT (constant rate of transverse) method. In this method, testing machine in which the pulling clamp moves at a uniform rate and the load is applied through the other clamp which moves appreciably to actuate a weighing mechanism, so that the rate of increase of load or elongation is dependent upon the extension characteristics of the specimen. Strip test is used to find the tensile strength of fabric. The raveled strip test in this test method is considered satisfactory for acceptance testing of commercial shipments of woven textile fabrics since the method has been used extensively in the trade for acceptance testing. The same is true for the cut strip test for felted or nonwoven textile fabrics. The method is not recommended for knitted fabrics because of their high stretch.

In this experiment actually the breaking force of the fabric is calculated, which is the maximum force applied to a material carried to rupture. This breaking force is the tensile strength of the fabric. This breaking force is also called the breaking point, breaking load, breaking strength and force-to-break the fabric.

Objectives:

- Determine the tensile strength of the fabric.

- Determine the tensile strength in warp-wise and weft-wise directions of the fabric.

Materials & Equipment:

- Scissor

- Cotton fabric

- Tensile testing machine

- Inch Scale

Procedure:

- Cotton fabric was taken.

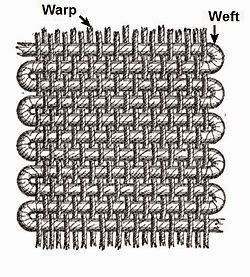

- Warp and weft direction of the fabric was identified.

- Two strips were cut from the fabric in both directions having dimensions of 6"x2.5".

- Two marks were made on the strips in the width dimension, 0.25" inside from the edges.

- Pull out the yarns outside these marks to make the width 2".

- The specimen was mounted securely in the clamps of the testing machine. The specimen were centrally located and the long dimension was as nearly parallel as possible to the direction of force application. It was sure that the tension on the specimen was uniform across the clamped width.

- The machine was operated and the specimen breaks or ruptures.

- The breaking force was noted.

Observations & Calculations:

Weft-wise fabric strength

Sr. #

|

Tensile Strength (Kg)

|

1

|

82

|

2

|

88

|

3

|

80

|

4

|

76

|

5

|

78

|

Mean Values

|

81

|

Warp-wise fabric strength

Sr. #

|

Tensile Strength (Kg)

|

1

|

112

|

2

|

110

|

3

|

120

|

4

|

113

|

5

|

114

|

Mean Values

|

114

|

Results & Discussion:

Tensile Strength

Weft-wise tensile strength = 81 Kg

Warp-wise tensile strength = 114 Kg

The results show that the warp-wise tensile strength of the fabric is more than that of the weft-wise tensile strength of the fabric. There are many factors responsible for this:

- The warp yarn has size material on it applied during the weaving preparation process, while weft yarn has no size material.

- The ends/inch of the fabric is more than that of picks/inch of the fabric.

Conclusion:

This experiments showed that the warp-wise tensile strength of fabric is greater, hence the fabric is more stable along the warp-wise direction.

The raveled Strips Test in this test method is considered satisfactory.

ReplyDeleteAn leading post shared. Thanks for sharing amazing information with us.

ReplyDeletestone washing

Hello There, this article was very helpful. But I have a query. What would be the maximum weight that 1meter x 1meter of the above fabric be able to withstand without tearing? How do you arrive at this based on the breaking strength that has been calculated?

ReplyDeleteAwesome Blog! Its very interestingly and informative in reading. This is really a great Stuff for sharing. Keep it up. Thanks for sharing.

ReplyDeleteBox Compression Tester | Testing Instruments

Good blog!HOW about this machine Tensile Strength Tester

ReplyDelete?

I have just gone through your blog......your information is so valuable. Thanks for sharing this information. ABS Instruments Pvt. Ltd. is a Thirty Years old company that supplies the best in materials testing equipment from all over the world to our customers in India. Tensile sample preparation

ReplyDeletePresto Group is a leading manufacturer and supplier of universal tensile testing machine in India. Universal tensile testing machines are used to measure the tensile strength, elongation, modulus, and other mechanical properties of various materials, such as metals, plastics, rubber, textiles, etc. Presto Group offers a range of universal tensile testing machines that can perform different types of tests according to various national and international standards and specifications. Presto Group has branches in Mumbai, Kolkata, Chennai and Delhi, and also exports its products to various countries. Presto Group is committed to delivering high-quality products and services at competitive prices. For more information about Presto Group and its universal tensile testing machines, please visit their website or contact them at +91 9210 903 903 or info@prestogroup.com.

ReplyDelete